Unveiled Exploring Breakaway Couplings in Industrial Applications

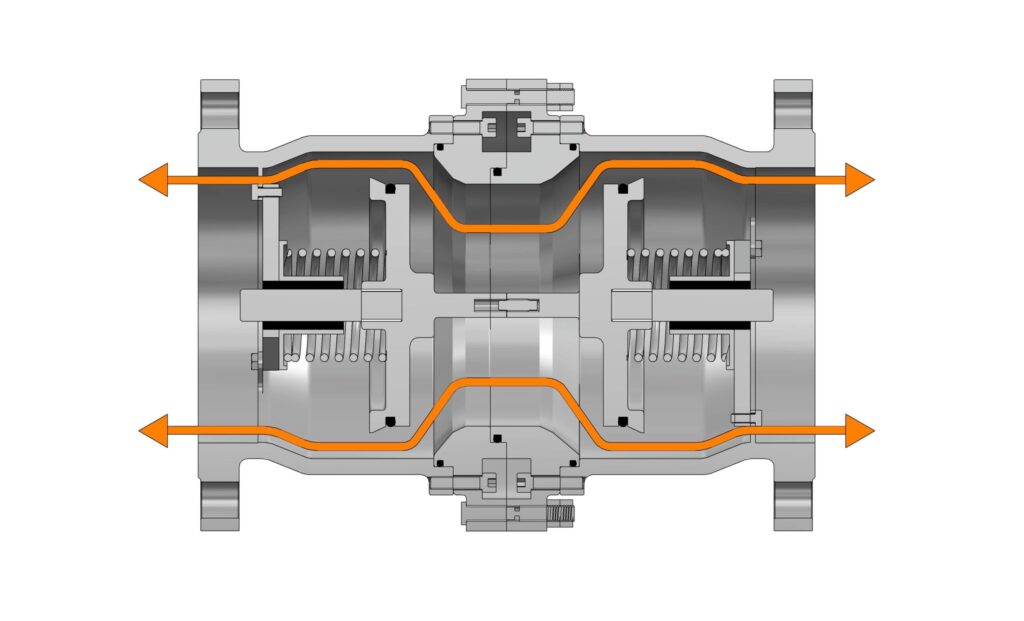

Breakaway couplings play a pivotal role in enhancing safety and efficiency within various industrial applications. These critical components are designed to provide a swift and controlled separation of two connected sections in the event of an emergency, preventing catastrophic consequences. One of the key components of breakaway couplings is the release mechanism. Typically, a breakaway coupling comprises a mechanism that responds to a specific force or pressure, triggering the separation of the connected parts. This release mechanism is meticulously engineered to ensure a rapid response while maintaining reliability and precision. In industrial applications, where the transportation of fluids or gases is commonplace, breakaway couplings are often employed to mitigate the risks associated with accidental disconnections. The coupling consists of two main parts: the male and female halves. The male half is connected to one section, while the female half is connected to the other.

A critical component in this configuration is the ball and cone valve system. This system ensures that when the coupling is intact, the ball and cone create a sealed connection, preventing any leakage or spillage. However, in the event of an abrupt force or excessive pressure, the ball and cone valve system is designed to disengage, allowing for a rapid separation of the two halves. Furthermore, the materials used in the construction of breakaway couplings are of paramount importance. These components are often exposed to harsh environmental conditions, including extreme temperatures and corrosive substances. As a result, materials such as stainless steel, high-grade alloys, and durable polymers are commonly employed to ensure the longevity and resilience of breakaway couplings. The choice of materials also contributes to the overall effectiveness of the release mechanism, as they must withstand the forces involved in the separation process without compromising the integrity of the coupling.

Another critical aspect is the resetability of breakaway couplings. After a disconnection event, it is essential for these couplings to be easily reset without the need for extensive maintenance or replacement. This ensures minimal downtime in industrial processes, allowing for a swift return to normal operations. The resetability feature is often achieved through a straightforward manual or automated process, enabling operators to quickly re-engage the coupling for continued use. In conclusion, breakaway couplings are indispensable components in industrial applications, safeguarding against potential disasters by providing a reliable and efficient disconnection mechanism. The release mechanism, ball and cone valve system, choice of materials, and resetability are critical components that collectively contribute to the overall effectiveness and reliability of these safety devices. As industries continue to prioritize safety and operational efficiency, the evolution of breakaway coupling technologies remains essential in meeting the ever-growing demands of a diverse range of applications.